LED Light Color Consistency

Light color consistency became a concern among lighting professionals ever since the traditional incandescent light sources were replaced by newer energy saving lighting technologies, like fluorescent or HID (High-Intensity Discharge lamps). Since the introduction of LED lighting, light color consistency has become an even bigger concern. Continue reading to learn more about the color consistency for LED light.

What is light color consistency?

The simplest way to tell color consistency in a lighting environment is whether it is noticeable or not. Light colors are consistent if they are not noticeable.

Light color consistency plays an important role in achieving high-grade lighting designs. In order to understand how light color consistency will impact our overall lighting environment, or how to evaluate this factor in our lighting decisions, we need to firstly know some core concepts about light color and how it is perceived by the human eye.

What is light color and how to define specific color points on CIE chromaticity diagram?

Same as brightness, color is another basic, critical factor of light. Light color is routinely overlooked by most people but is apparent when not attended to well.

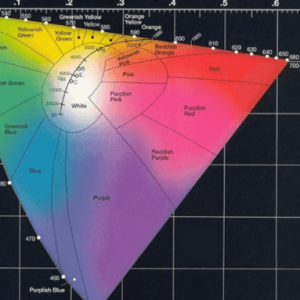

Depending on the range of wavelengths in visible light spectrum given by one particular light source, this light can be perceived as a specific color, including whites in various tones.

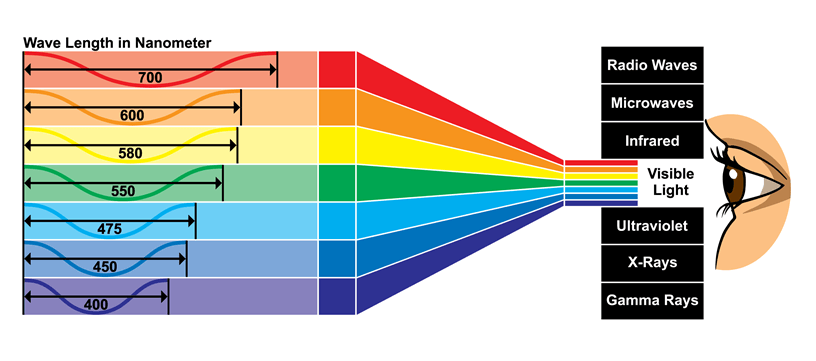

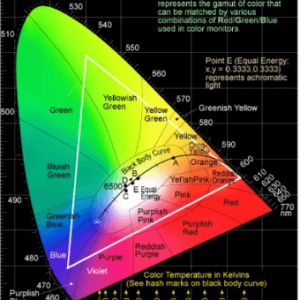

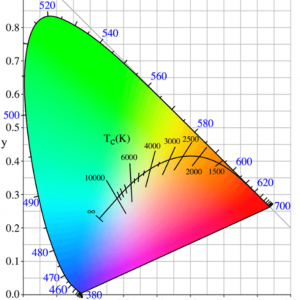

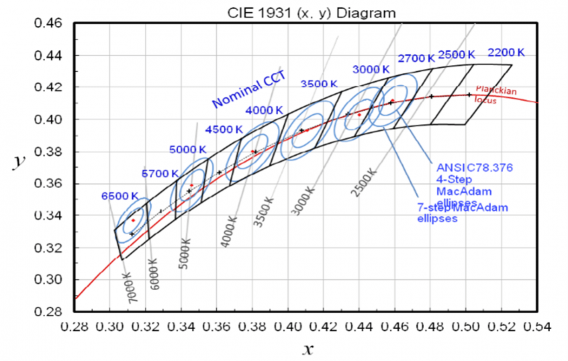

Light color is specified by chromaticity coordinates plotted on a 2D diagram firstly created in 1931 by the CIE (International Commission on Illumination). The CIE 1931 chromaticity diagram maps how the distribution of different wavelengths in visible spectrum can create specific colors as perceived by the human eye.

The CIE 1976 chromaticity diagram (also called CIELUV) was created later, attempting to provide a more uniform diagram by more closely matching human color-difference sensitivities for all colors. Although the CIE 1976 (u’, v’) chromaticity diagram is more uniform and therefore superior for determining color difference or color shift (∆u’v’), the CIE 1931 (x, y) chromaticity diagram is still frequently used.

The CIE chromaticity diagram is usually shown with a solid line crossing over it, which is known as the Blackbody Locus or Planckian Locus. As per definition in Wikipedia, the Planckian Locus or Blackbody Locus is the path or locus that the color of an incandescent blackbody would take in a particular chromaticity space as the blackbody temperature changes. It goes from deep red at low temperatures, through orange, yellowish white, white, and finally bluish white at very high temperatures.

Based on the color appearances of the Blackbody or Planckian radiator at different temperatures, CCT – Correlated Color Temperature – is defined. The CCT of a light source, given in kelvin (K), is the temperature at which the heated blackbody most closely matches the color of the light source in question.

For white LED light, CCT covers the color appearance of the light, which normally could range from 2200K to 6500K. A CCT of 2200K appears as warm yellowish white, while 6500K appears as cold bluish white.

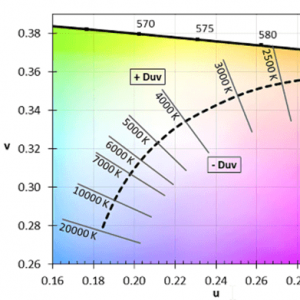

Crossing over the Blackbody Locus, there are also some short lines, named as CCT lines. Color points lying on the CCT lines, above or below the Blackbody Locus, are still in the same CCT but carrying a greener or pinker tint, as compared to the color points lying directly on the Blackbody Locus.

Thus, a signed metric, +/- Duv, is introduced as the closest distance from the color point to the Blackbody Locus. Duv with a positive sign (+) refers to distance above the Blackbody Locus, while a negative sign (-) below it.

With the introduction of Blackbody Locus and CCT lines, white light – in addition to specific chromaticity coordinates – could also be defined by a target CCT with specified Duv. Added together, a specific CCT value and Duv value correspond to a specific pair of chromaticity coordinates.

Following on from what has been explained above, you can see now why “3000K” is not a unique value for describing light colors. Instead, the more specific way to describe a unique light color point is “3000K, Duv +0.0007”, or a set of chromaticity coordinates such as “0.2483, 0.5202”.

What is light color deviation and how to quantify it?

Now we understand what light color is and how to specify it. Each color point on the CIE chromaticity diagram represents a unique light color.

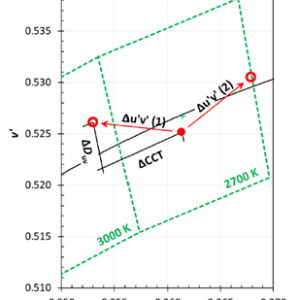

The distance between two different light color points are measured as Δu’v’. As a magnitude metric, Δu’v’ describes how much the color deviation is, but not the direction towards which the color has shifted. So even if the Δu’v’ value is the same, the light color could look different depending on whether the deviation is more towards the yellowish tint or pinkish tint. (need to create two light beams in 3000K but one looks more yellowish and another more pinkish). Δu’v’ is one way to quantify the light color deviation and communicate chromaticity tolerances.

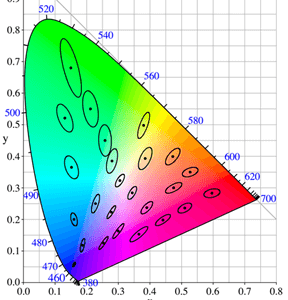

Another and more popular way to communicate light color deviation is MacAdam ellipses. In order to investigate visible color difference, Dr. David MacAdam performed a series of experiments in 1942. He showed different color swatches to a group of people and came to a determination of when the observer could see the difference in color.

These experiments resulted in a series of ellipses, which became known as MacAdam ellipses, that are measured in the unit called “step”. One step of MacAdam ellipse defines a unit of ‘just noticeable’ color difference. The more the steps, the bigger the differences.

The area of the MacAdam ellipse is different for different colors on the chromaticity diagram, meaning people have different sensitivity in discriminating different colors. One step of MacAdam ellipse is also known as one SDCM – Standard Deviation Color Matching.

MacAdam ellipses / SDCM steps provide a simple and easy-to-understand system for communicating acceptable light color tolerances.

Another and more popular way to communicate light color deviation is MacAdam ellipses. In order to investigate visible color difference, Dr. David MacAdam performed a series of experiments in 1942. He showed different color swatches to a group of people and came to a determination of when the observer could see the difference in color.

What are the current industry norms and standards regulating light color tolerances?

Existing standards and regulations in the US market for lighting products that define light color tolerance mainly include ANSI standards, ENERGY STAR® and DLC® requirements, California JA8 and Title 20 requirements etc.

ANSI (America National Standards Institute) created ANSI C78.376 for defining color deviation tolerances for fluorescent light sources first, where 4-steps SDCM are used as the tolerance for the 6 listed nominal CCTs from 2700K to 6500K. Later when it came to the current era of Solid-State Lighting (SSL), ANSI C78.377 was introduced for LED light sources, where ten nominal CCTs of white LED light are listed from 2200K to 6500K, plus a system for calculating the tolerances for non-listed flexible CCTs.

In ANSI C78.377, instead of MacAdam ellipses, a quadrangle area plotted on the CIE chromaticity diagram is given for each nominal CCT. The size of each 7-steps quadrangle corresponds approximately to that of 7-steps MacAdam ellipse, but with adjusted center points in order to be continuous without any gaps or overlaps between each other.

According to ANSI, quadrangles rather than ellipses are used for LED products for several reasons. Firstly, quadrangles are commonly used in the chromaticity binning of LED products. Secondly, the continuous quadrangle areas allow cost-effective binning selection. Lastly, quadrangles can be specified by the CCT and Duv, thus making it easier to judge product acceptance using the quadrangles.

Considering LED lighting is still in its early stage of development, and the accuracy of control for light chromaticity is not as developed as for earlier technologies, the existing ANSI standard allows for 7-steps quadrangle, close to 7-steps SDCM, as LED light color deviation tolerance.

ENERGY STAR and DLC adopted the same level of 7-steps quadrangle also in their requirements. California JA8 and Title 20 requirements have tighter tolerances as 4-steps. These norms and standards keep being updated periodically and you are always encouraged to check for the latest version.

With the development of LED technology and manufacturing processes, it is commonly acknowledged that tighter tolerances shall and can be met, especially for applications where light color consistency is critical for creating overall appealing and aesthetic lighting environments, or in order to meet the expectations and requirements of lighting designers and end users.

GREEN CREATIVE offers products powered by TRUE CHROMA providing light with minimum 3 SDCM tight color consistency. Also, products with TRUE CHROMA have the highest color accuracy standards per CRI and the new IES TM-30 method, which evaluates additional calculations when determining color accuracy. Learn more about TRUE CHROMA here. For other applications where light color consistency has less stringent requirements, you can choose our products with 4 SDCM range, or the basic 7 SDCM range. Click to see the details of our superior products offerings or contact us for more information.